In the business sector manufacturing is a critical thing which has to be completed at specified time without any errors. In reality it is not easy task to complete the manufacturing operations within time so people search for an alternative way like using manufacturing software. The manufacturing software is a modernized manufacturing software based tool which helps lot manufacturing companies to have control on their operations. This manufacturing software has ability to tackle all sorts of functional problems occurs in manufacturing process. Moreover this type of manufacturing software not only helps to have control but also helps for entire manufacturing process starting from raw material purchase till production process and customer delivery. Thus this manufacturing software helps lot to achieve company targets and increases the production and quality too. When it comes the usage of manufacturing software there are different types of software available were people use selective type based on the need.

Manufacturing software commonly used in industries:

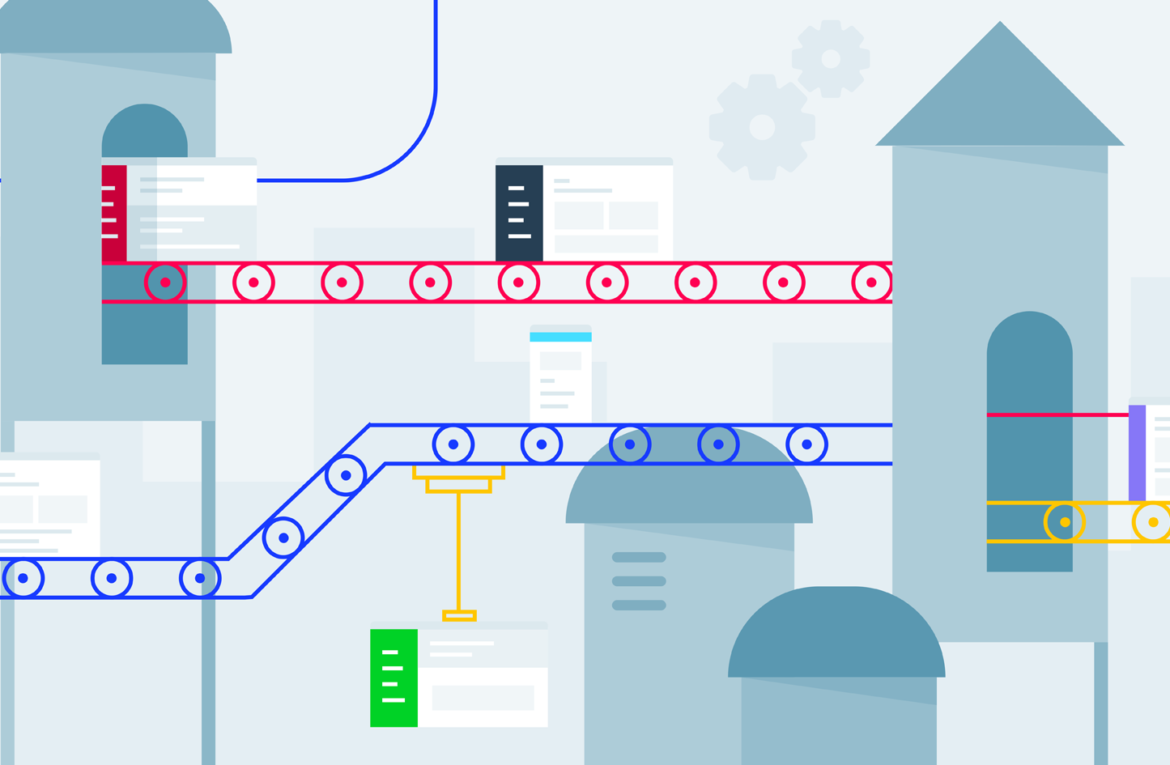

Even though there are several types of manufacturing software available manufacturing companies tends to use three main manufacturing software which remains as an essential one in all manufacturing companies namely.

- ERP- Enterprise Resource Planning

- MES- Manufacturing Execution System

- Process Control

The above three manufacturing software are widely used by most of the manufacturing companies.

ERP- Enterprise Resource Planning: this is one of the oldest software which is updated with newer version named as MRP II that is manufacturing resources planning II. This type of software is especially designed to sort out problems in sales and client care. The ERP software would track on several inputs such as recurring and standing orders, customer information and sales cycle. In addition with all these it also gives assistance in purchasing raw materials, planning and in process.

MES- Manufacturing Execution System: this type of software is used in production process. When it comes to manufacture companies produce different products all should need to be good enough. The MES software used to have control on quality product production. The software would have keen track starting from raw materials process till packing. This MES software avoids manufacturing defects products which in turn helps the company to maintain their reputation and deliver customer quality products at right time.

Process control: all the software directly gets involved into the production process but the process control software mainly focus on maintenance of machines and ensure they are working with proper conditions. Most of the time when manufacturing companies holds many machineries for heavy production all of sudden a problem occurs it is very difficult to find out the problem. In that case the process control software spot out the machinery condition then identify the faulted one and also the software decides whether the machine has to replaced or not. On other hand this software is also help to improve the quality in goods.

Thus all three manufacturing software remains as essential one but not all of them are used in companies instead based on the supplier need and manufacturing need the manufacturing software are bought for companies. This not only helps the companies to improve the quality of goods but also to be better competitor for other manufacturing companies.